With pressure on producers to trim costs while at the same time tackling the threat of food related illnesses, the system provides a highly-efficient labeling option and also a means of tracking down problematic shipments, according to the company.

JBT Product Development Engineer Jonathan Stokes, who was involved in the development of the system, explained, "FLEX-ID system helps obtain variable and trackable data on an individual piece of fruit. It is also able to reach the higher labeling speeds that customers are looking to achieve".

Traceability

The company says the FLEX-ID labeler’s traceable labeling system is the key selling point for the technology. Customers can create their own label layout, thus helping to trace where individual produce originated from. It does this by allowing users to add a lot code, as well as standard data such as the Price Look-Up (PLU) code and quantity.

“Our system keeps track of the lots,” said Stokes. “Let’s say you are running lemons, and four months later, someone gets sick. They can track down the lemon which made the person sick to the batch and a particular time, and that’s what gets recalled.”

JBT says there is a reported 48 million people that get sick and 3000 that die each year due to foodborne illnesses. Therefore, Stokes emphasized that there was clear need for effective tracking and isolation of any potentially contaminated products.

Time savings

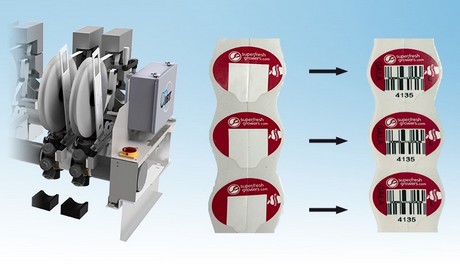

According to the company, the FLEX-ID system also allows customers to make time-saving and logistical changes by eliminating the need for manual replacement of labels. “Say I’m running large lemons which have their own PLU number, and then halfway through the day I switch to running small lemons with a different PLU number – typically what happens is you have to have someone walk out to the machine, pull off those labels, grab a new cassette which holds the new labels, drop it on the machine, and make sure it’s all good, which all takes time,” said Stokes.

“Most labels are pre-printed, so they don’t have any tracking information. With the FLEX-ID system, you go to your computer, change the setting to run small lemons, add in the PLU code and the lot number and it ends the previous lot, keeping track of when that lot stopped, records the new lot and sends the new label. From a logistics point of view, this also saves on having to stock rolls of 40 or 50 different labels,” he added.