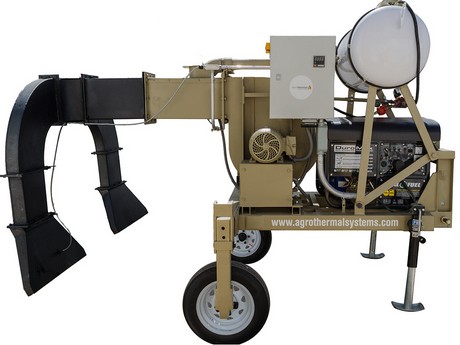

The Agrotherm XR1 is one of several new designs being made for Napa, Ca.-based Agrothermal Systems by Aeolo S.A.de C.V. of Querétaro, Mexico. The machine, which can treat both row and vertical crops thanks to a switch in the vent assembly, is self-contained and can be pulled by an ATV or Gator type vehicle in trailer mode. (It can also be lifted in three-point hitch configuration by a conventional farm tractor.) It extends the types of crop that its predecessor, the Agrotherm XT, can’t cover—think narrow row vertical crops such as cane berries, herbs and staked vegetables; vineyards 4.5’ to 6’ in width; or with a vent change, crops such as onions, strawberries, leafy greens, celery and potatoes.

“It’s a broad-scale non-residue methodology for treating insects and fungal problems,” says Marty Fischer of Napa, Ca.-based Agrothermal Systems , who notes that he sees growers increasingly responsive to new ways to control pests and insects. “There’s a growing awareness about using heat like this. Five years ago, there would have been much more scepticism compared to now. And there was less desperation then about the use of chemicals and their residues. But now some producers are eager to find alternatives and could be put out of business by residue levels or infestations they can’t control. So everyone is more open to sustainable alternatives.”

Different markets

He also notes that he sees a split market in terms of how comfortable a grower is still using chemicals to fight infestation. “It’s quite regionalized and divided,” says Fischer. “In Europe for example, there’s tremendous pressure to find non-chemical solutions. There’s also quite a movement by some governments to reduce the number of chemicals growers can use—some have been banned over the last 10-15 years. So there are fewer chemicals and the insects frequently develop resistance because they’re exposed to the same chemical over and over again.” There are also different types of growers both overseas and domestically who are interested in chemical alternatives, such as organic growers.

In using heat, the Agrotherm XR1 burns propane to create heat at approximately four gallons/hour costing $6-8 in the US per hour of use. The machine weighs some 1,750 lbs. and sells for $29,900 plus taxes and shipping.

While there are numerous applications for the Agrotherm XR1, Fischer notes that in starting out, Agrothermal’s focus is on the crops where it can prove its technology the quickest. “The simpler their infestation issues are, the easier it is for us to show the technology,” he says. “If you take a crop like green onions for example, the dominant pest are thrips and we can take a machine through a field and demonstrate the effectiveness of heat. That’s instant gratification for the grower.”

And while it can treat more complex multiple pest issues on crops such as apples or wine grapes, the results may not be seen until the end of the season.

Fischer, who says that more technology information and scientific studies are available upon request, adds that there are also other benefits from the heat treatment. These include higher phenol and antioxidant levels, which are a result of the heat activating the natural self defence system of plants. In turn, this process creates a more flavorful fruit and a higher phenol, which is a preservative that can help extend shelf life.