“We are looking forward to exhibiting at MetPack and we have a great line up of technologies that will make all the difference to our customers’ canmaking operations worldwide,” said Marc Hoche, Head of Sales at CMB Engineering. “For 2014, we are not only excited to showcase our latest solutions but also to celebrate CMB Engineering’s 50th anniversary of providing superior equipment and support from our headquarters in Shipley, Yorkshire.”

2014 marks the first occasion that CMB Engineering will be exhibiting the company’s best-selling canmaking equipment at the show.

Developed with a unique Standby Mode feature that is designed to maximize energy efficiency and thus reduce running costs, the CMB 5610 Canmaker enables companies to offer competitive flexibility by producing multiple can sizes of up to 568ml on the same machine with just a simple changeover. Featuring an integrated trimmer, the CMB 5610 Canmaker also facilitates simplified toolpack integration, further improving operational efficiency.

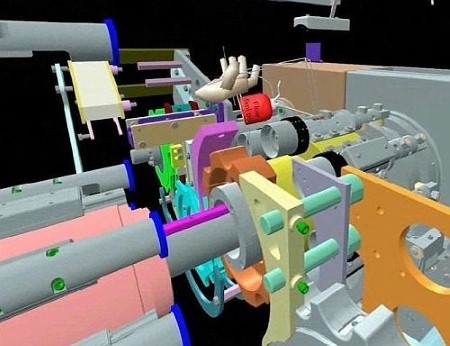

Taking customer support a step further, CMB engineering will be demonstrating the company’s interactive 3D software solution, which enables customers worldwide to remotely examine the canmaking machinery in detail. With the ability to remove elements of the machine and closely view moving parts in action, the interactive virtual reality experience allows CMB Engineering to train its customers on the canmaking equipment. Engineers are now able to explore the company’s machinery in 3D and further their understanding of the equipment’s features and benefits without the need for teams to be present on-site.

Complementing CMB Engineering’s technology display will be examples of the company’s latest cupping die set, which has been developed to be compatible with all press types for both steel and aluminum cups. Produced to precise manufacturing tolerances, the die set is designed to safeguard the consistency and quality of each cup from the very beginning of the manufacturing line.

“As regular exhibitors at MetPack, we appreciate and benefit from the show’s international exposure to the metal packaging industry,” Hoche concluded. “It is a terrific opportunity to display our latest technologies and strengthen relationships with our global customers, demonstrating the strong commitment to excellence and quality that is at the heart of CMB Engineering.”