machine supplier for the can making and canning industry, will present a highly efficient Can Former from their CF series at this year’s METPACK in Essen (Germany).

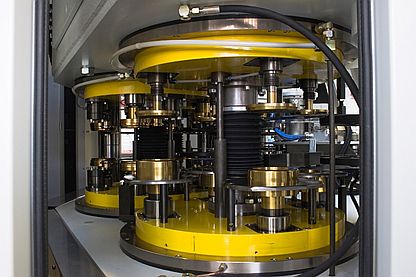

machine supplier for the can making and canning industry, will present a highly efficient Can Former from their CF series at this year’s METPACK in Essen (Germany). The LANICO Can Former CF 411 is a highly efficient and versatile solution for medium and high speed general line can production. It is the only Combination Machine worldwide that unites a wide working range from 73 millimetres up to 200 millimetres diameter as well as exceptionally quick change-overs and a high production speed of up to 300 cans per minute. The machine is particularly suitable for the production of three piece welded necked-in or straight walled general line cans. The CF 411 is typically applied for producing large milk powder cans, beer kegs, large paint cans and all kinds of large food cans and general line cans. Equipped with three carousels, the Can Former offers utmost reliability and flexibility for different material specifications. A variety of mountable toolsets allows numerous operations to be performed as for instance necking, flanging, bottom and top end seaming. Further options are beading, die-necking, spinflanging and curling.

The welded can bodies are fed vertically to the machine. They are separated by infeed spirals and transported to the first of up to two flanging or necking and flanging carousels. As a next step, the can bodies are transferred to the following carousels by means of synchronised star wheels for beading or seaming bottom and top ends. Further optional operations are die-necking, spinflanging and curling.

One of the technical highlights of the CF 411 is the “Express Dia Change” system, which minimises downtimes. The use of modular change parts allows diameter changes to be completed within a short time. Further adjustments are minimised by pre-set change parts. The motor driven adjustment system of the CF 411 permits height changes to be performed within seconds, tool-free and absolutely accurate.

Thanks to the feature that spindle speed can be set individually for each turret, the CF 411 is not limited to a fix relation of spindle rotation to turret rotation. The required spindle speed data can be entered into the machine’s Recipe Management System or by individual input at the touch panel. Thus rotation speed can be matched exactly with the requirements of the tinplate material and the decoration.

The LANICO Can Former CF 411 will be on show at METPACK in Essen (Germany) from May 06 to 10, 2014 (Hall 3.0, booth H10).