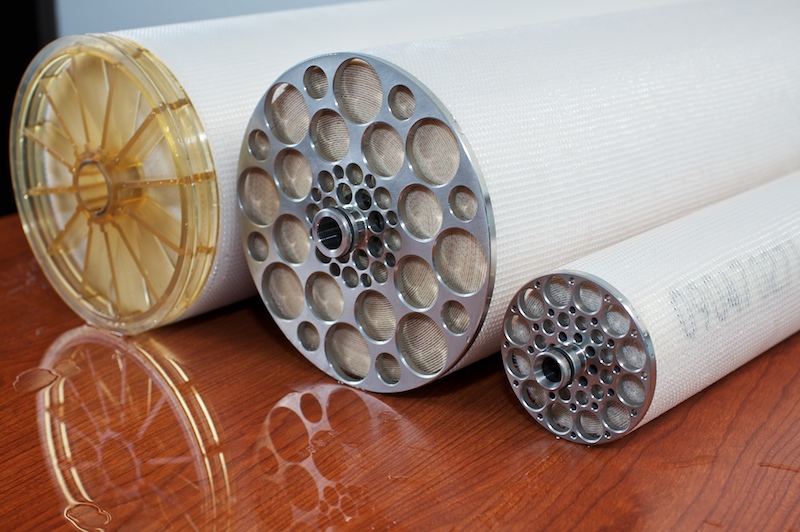

and manufactures spiral wound membrane elements for specialty applications. The company offers Reverse Osmosis, Nanofiltration, Ultrafiltration, and Microfiltration membrane elements in sanitary design for use in Food, Dairy, Beverage, Pharmaceutical and Heat Sanitisable applications. Toray manufactures using a wide range of materials and feed spacers to suit most application needs.

and manufactures spiral wound membrane elements for specialty applications. The company offers Reverse Osmosis, Nanofiltration, Ultrafiltration, and Microfiltration membrane elements in sanitary design for use in Food, Dairy, Beverage, Pharmaceutical and Heat Sanitisable applications. Toray manufactures using a wide range of materials and feed spacers to suit most application needs.The year 2007 marked the completion of a major investment to start membrane manufacturing in the USA. The first full year in sales of specialty (sanitary) elements came a year later and Toray commenced activities in Europe in 2010. Sales quickly grew to the point where Toray needed to review how to better serve its European market.

At the start of 2013 responsibility for sales and marketing transferred from sister company and manufacturing headquarters, Toray Membrane USA to Toray Membrane Europe.

This has allowed Toray to apply more resources (staff) locally and therefore be more responsive to client needs and to carry stock in Europe (Germany) which also benefits customers in reduced shipping costs and gives them the ability to procure commonly required membrane elements at short notice.

Toray has a full suite of RO and UF membranes to meet the growing needs in an increasingly sophisticated dairy processing environment.

With over five years of proven commercial performance Toray’s standard 10K Dalton and its high rejection derivative have set new standards in true protein retention and excel in WPC and WPI applications, especially at high protein concentrations.

In the last year Toray has introduced a NF membrane specific for desalting of dairy streams and a MF membrane for whey/WPC defatting.