Epidemiologic studies have demonstrated an inverse association between consumption of fruit products and morbidity and mortality from degenerative diseases. The antioxidant content of fruits may contribute to the protection they offer from disease. Because fruits contain many different classes and types of antioxidants capable of scavenging free radicals (Pellegrini et al., 2003). The antioxidant activity of any fruit product is due to putative modes of action of specific flavonoids as bioactive components. It is also well-correlated with the total phenolic and vitamin C content of the corresponding fruit product. In general, fruits rich in anthocyanins (e.g. strawberry, raspberry and red plum) demonstrate the highest antioxidant activities, followed by those rich in flavanones (e.g. orange and grapefruit).

Fruit beverages have their unique identities having large content of micronutrients, polyphenols, vitamins, flavonoids and other nutritional compounds. Characteristic appearance and flavour distinguish among various fruit-based beverages like juice, squash and ready-to-serve (RTS) beverages. Main concern of this beverage industry is the stability of the products throughout the post-processing storage. Thermal treatment as means of preservation of these products is the common process implemented so far. However, the application of heat renders a negative impact on the nutritional quality, appearance and taste of these (Awuah et al., 2007). Vitamins are the major heat-sensitive constituents among them, vitamin C is the least resistive to heat. It is more prominent in case of non-citrus beverage. The degradation reactions like oxidation, non-enzymatic reaction, pigment destruction and condensation are responsible to exploit the nutrient content in the beverage. Today’s consumer demand for minimally processed fruit products and “natural” fruit products tend to think of alternative thermal processing.

High Pressure Processing (HPP), a relatively new concept compared to conventional thermal processing, also sometimes known as High Hydrostatic Pressure (HHP), or Ultra High Pressure (UHP) processing, is a non-thermal food processing method that subjects liquid or solid foods, with or without packaging, to pressures ranging between 50 and 1,000 MPa. HPP has already been established itself as an alternative to thermal processing. In food processing it is of great interest due to its ability to inactivate food-borne microorganisms and enzymes, at low temperature, without the need for chemical preservatives and it is less detrimental than thermal processes to low molecular weight food compounds such as flavouring agents, pigments, and vitamins, as covalent bonds are not affected by pressure. Pressure-treated foods have sensory properties similar to fresh products, which is a major advantage in fruit processing as it matches consumer demand for healthy, nutritious and ‘‘natural’’ products. HPP of fruit products offers the chance of producing food of high quality, greater safety and increased shelf life (Chakraborty et al., 2014).

2 High Pressure Processing (HPP)

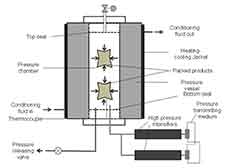

The basis for applying high pressure to foods is to compress the water surrounding the food. At room temperature, the volume of water decreases with increase in pressure. Because liquid compression results in a small volume change, high pressure vessels using water do not present the same operating hazards as vessels using compressed gases. High pressure can be generated by direct compression; indirect compression and heating of the pressure medium. Indirect compression uses a high pressure intensifier to pump a pressure medium from a reservoir into a closed high pressure vessel until the desired pressure is reached.

In batch-wise HPP systems, the product is generally treated in its final primary package; commonly, the food and its package are treated together and so the entire pack remains a ‘secure unit’ until the consumer opens it. Batch-type processing has been a preferred method for HPP of packaged fluid foods, thus eliminating any danger of cross contamination by the medium. The food is prepared and aseptically filled/sealed in flexible packaging, then placed in a pressure chamber for pressurising using a suitable Pressure Transmitting Medium (PTM). Pressurisation is done by pumping the medium either into the vessel or into the intensifier using High Pressure Pump (Fig. 1).

3 Effect of HPP on Antioxidants in Fruit Beverages

The application of pressure had minimal effect on the covalent bonds which are the backbone of nutrient compounds in the fruit beverages like phenolic compounds, ascorbic acid, anthocyanin, carotenoids and flavonoids. These are mainly responsible for showing antioxidant capacity of the product. The reason is high pressure more likely affects the non- covalent bonds like hydrogen bond, and hydrophobic interactions, where compaction in volume can take place. Meanwhile, covalent bonds which are the backbone of these low-molecular-weight compounds remain unaffected by the pressure. Thus, one of the major advantages of using HPP in fruit beverage processing is that the pressure-treated products mimic the sensory properties of fresh produce (Oey et al., 2008). The studies regarding the antioxidant capacity of the high pressure treated fruit beverages revealed that HPP had least effect on this property except at higher temperatures as summarised in Table 1.

Butz et al. (2003) studied the influence of HPP (600-800 MPa/25-44 °C/6 min) on antioxidative factors and also on vitamin C and carotenoids in juices from oranges, apples, peaches also from mixed citrus juices. The authors reported no significant difference in water-soluble antioxidant capacities between the pressure treated and the control samples. The antioxidative capacity of the samples against hydroxyl radicals also followed the same.

Sanchez-Moreno et al. (2005) studied the effect of HPP (400 MPa/40 °C/1 min) on the radical scavenging capacity of orange juice. HPP treatment did not modify the antioxidant activity of the sample because the contribution of phenols to the antioxidant activity in sample was low. HPP at low temperature of 40°C led to a relative increase in the case of hesperetin but not in naringenin content despite an increase in flavone content was obtained in the treated sample when compared with fresh juice.

In another study conducted by Plaza et al. (2006), freshly squeezed orange juice was processed by HPP at 400 MPa/36-40 °C/1 min and the stability of vitamin C and antioxidant activity was studied just after treatment and during 40 days of refrigerated storage at 4°C. They found that a significant decrease of about 8% in ascorbic acid content after HPP, whereas, the loss in antiradical scavenging capacity immediately after treatment was 5%. At the end of refrigerated storage, HPP treated juice showed similar 14% vitamin C loss with respect to untreated juice; whereas, the antioxidant activity was reduced by 19% from day 0.

Dede et al. (2007) treated tomato juice within the domain of 250 MPa/25-35 °C/5-15 min and monitored the antioxidant capacity and ascorbic acid content during storage at 4 and 25°C up to 30 days. More than 92% ascorbic acid content in sample was retained immediately after HPP. The maximum loss in antioxidant capacity was 10% obtained at 250 MPa/35 °C/15 min. The ascorbic acid content of pressurised tomato juices, when stored at both 4 and 25 °C, remained over 70% after 30 days of storage. HPP-treated juice showed a small loss of antioxidants (below 10%) during storage.

Barba et al. (2013) investigated the impact of HPP at different pressure (200, 400 and 600 MPa) and treatment times (5, 9 and 15 min) on ascorbic acid, total phenolics, anthocyanin stability and total antioxidant capacity of blueberry juice. HPP treatments resulted in more than 92% vitamin C retention at all treatment intensities. Meanwhile, total phenolic content in the juice was increased, mainly after HPP at 200 MPa for all treatment times. The total and monomeric anthocyanins were similar or higher than the value estimated for the fresh juice being the maximum at 400 MPa/15 min (16% increases). Antioxidant capacity values were not statistically different for treatments at 200 MPa for 5–15 min in comparison with fresh juice, however for 400 MPa/15 min and 600 MPa for all times (8–16% reduction), the lowest values were observed for total antioxidant capacity determined.

Varela-Santos et al. (2012) evaluated the effect HPP conditions (350-550 MPa/15-20 °C/0.5-2.5 min) on the bioactive compounds of pomegranate juices during 35 days of storage at 4 °C. All HPP-treated samples showed a slight reduction in antioxidant capacity during storage time. Phenolic content increased significantly between 3% and 12% for treated samples with 350 MPa and 550 MPa at day 0. The DPPH scavenging activities of the pomegranate juice expressed as an IC50 value were ranged from 11 to 20 mg/mL at day 0. The treated sample at 450 MPa and 550 MPa exhibited the strongest antioxidant capacity (11–13 mg/mL), followed by the control sample (14 mg/mL) and 350 MPa (15–18mg/mL) which showed the weakest activity at day 0.

Pozo-Insfran et al. (2007) evaluated the effect of HPP (450-550 MPa/25 °C/15 min) on antioxidant capacity of Muscadine grape juice during the storage of 21 days at 25 °C. Higher anthocyanin losses occurred at 400 MPa (70%) than at 550 MPa (46%), which were correlated to antioxidant losses. Similarly, greater ascorbic acid losses were observed at 400 MPa (84%) than at 550 MPa (18%). In stored samples, higher anthocyanin content (>2-fold) and antioxidant capacity (>1.5-fold) was observed for copigmented treatments when compared to control juices.

Barba et al. (2012) investigated the effect of HPP (100-400 MPa/20-25 °C/2-9 min) on ascorbic acid, total phenolics, anthocyanin stability and total antioxidant capacity of orange juice–milk beverage. Ascorbic acid retention in the beverage was higher than 91% in all cases after HPP. There was a significant increase (p<0.05) in phenolic compounds at 100 MPa/7 min, however at 400 MPa/9 min, it was observed a non-significant decrease. Total carotenoid content was significantly higher in all samples treated by HPP when treatment time was 7 and 9 min. HPP samples treated at 100 and 300 MPa had significantly lower antioxidant capacity.

Fernández García et al. (2000) compared the antioxidant capacity of HPP treated (400-600 MPa/40-60 °C/5-30 min) apple juice samples during storage at 4 °C. When freshly squeezed apple juice was tested, high pressure treatments were more deleterious than high temperatures, although more than 75% of the total capacity was preserved after extreme conditions (600 MPa/60 °C/30 min). After one month of storage at 4 °C, antioxidant potential of apple juice remained comparable to the one of fresh apple juice at same condition.

Jayachandran et al. (2015) studied the impact of HPP (200-600 MPa/30-70 °C/0-20 min) on the bioactive components in a litchi juice-coconut water-based mixed beverage. An increase in phenolic content (3–12%) and total antioxidant capacity (1–19%) was obtained in the treated beverage samples at 500 and 600 MPa. More than 95% of ascorbic acid has been retained at 30 °C; and it decreased at higher temperature like 60-70 °C.

The increase in antioxidant activity value detected during juice and beverage processing could be due to the extraction of some of the hydrolysable tannins, present in the fruit rind, and/or related to the increase in phenolics or ellagic acid, ellagic structures polymerised into ellagitannins, and/or anthocyanin polymers formed during the storage period. Reported loss after extreme high pressure conditions may have been generated by changes in juice redox properties during pressure build-up or by adiabatic heating of the samples inducing chemical reactions (Fernández García et al., 2000). In presence of oxygen, oxidative processes occurred rapidly and storage increased extensive losses. High pressure was in these cases markedly beneficial directly after treatment.

4 Concluding Remarks

Increasing market for fruit juice and beverages induced the industry people to ensure their stability, and also to avoid unpleasant aspects like off-flavour formation, while extending shelf-life of the final produce. This triggers the necessity of searching for new ways of processing like high pressure processing of these products. Different studies on the fruit-based beverages presented guarantee high pressure as a promising technique being non- detrimental and even advantageous for the total antioxidant profile of the juice or beverage. These compounds may be affected at higher pressures like more than 800 MPa which results in degradation in vitamins and fragmentation of larger flavouring compounds. The temperature associated with high pressure are the major contributing factor behind the thermal degradation of these bioactive components. However, more emphasis is required for specific beverages to find out the optimum treatment condition satisfying the consumer demand for safety, stability and nutritional quality.

The application of pressure had minimal effect on the covalent bonds which are the backbone of nutrient compounds in the fruit beverages like phenolic compounds, ascorbic acid, anthocyanin, carotenoids and flavonoids. These are mainly responsible for showing antioxidant capacity of the product. The reason is high pressure more likely affects the non- covalent bonds like hydrogen bond, and hydrophobic interactions, where compaction in volume can take place. Meanwhile, covalent bonds which are the backbone of these low-molecular-weight compounds remain unaffected by the pressure. Thus, one of the major advantages of using HPP in fruit beverage processing is that the pressure-treated products mimic the sensory properties of fresh produce (Oey et al., 2008). The studies regarding the antioxidant capacity of the high pressure treated fruit beverages revealed that HPP had least effect on this property except at higher temperatures as summarised in Table 1.

Butz et al. (2003) studied the influence of HPP (600-800 MPa/25-44 °C/6 min) on antioxidative factors and also on vitamin C and carotenoids in juices from oranges, apples, peaches also from mixed citrus juices. The authors reported no significant difference in water-soluble antioxidant capacities between the pressure treated and the control samples. The antioxidative capacity of the samples against hydroxyl radicals also followed the same.

Sanchez-Moreno et al. (2005) studied the effect of HPP (400 MPa/40 °C/1 min) on the radical scavenging capacity of orange juice. HPP treatment did not modify the antioxidant activity of the sample because the contribution of phenols to the antioxidant activity in sample was low. HPP at low temperature of 40°C led to a relative increase in the case of hesperetin but not in naringenin content despite an increase in flavone content was obtained in the treated sample when compared with fresh juice.

In another study conducted by Plaza et al. (2006), freshly squeezed orange juice was processed by HPP at 400 MPa/36-40 °C/1 min and the stability of vitamin C and antioxidant activity was studied just after treatment and during 40 days of refrigerated storage at 4°C. They found that a significant decrease of about 8% in ascorbic acid content after HPP, whereas, the loss in antiradical scavenging capacity immediately after treatment was 5%. At the end of refrigerated storage, HPP treated juice showed similar 14% vitamin C loss with respect to untreated juice; whereas, the antioxidant activity was reduced by 19% from day 0.

Dede et al. (2007) treated tomato juice within the domain of 250 MPa/25-35 °C/5-15 min and monitored the antioxidant capacity and ascorbic acid content during storage at 4 and 25°C up to 30 days. More than 92% ascorbic acid content in sample was retained immediately after HPP. The maximum loss in antioxidant capacity was 10% obtained at 250 MPa/35 °C/15 min. The ascorbic acid content of pressurised tomato juices, when stored at both 4 and 25 °C, remained over 70% after 30 days of storage. HPP-treated juice showed a small loss of antioxidants (below 10%) during storage.

Barba et al. (2013) investigated the impact of HPP at different pressure (200, 400 and 600 MPa) and treatment times (5, 9 and 15 min) on ascorbic acid, total phenolics, anthocyanin stability and total antioxidant capacity of blueberry juice. HPP treatments resulted in more than 92% vitamin C retention at all treatment intensities. Meanwhile, total phenolic content in the juice was increased, mainly after HPP at 200 MPa for all treatment times. The total and monomeric anthocyanins were similar or higher than the value estimated for the fresh juice being the maximum at 400 MPa/15 min (16% increases). Antioxidant capacity values were not statistically different for treatments at 200 MPa for 5–15 min in comparison with fresh juice, however for 400 MPa/15 min and 600 MPa for all times (8–16% reduction), the lowest values were observed for total antioxidant capacity determined.

Varela-Santos et al. (2012) evaluated the effect HPP conditions (350-550 MPa/15-20 °C/0.5-2.5 min) on the bioactive compounds of pomegranate juices during 35 days of storage at 4 °C. All HPP-treated samples showed a slight reduction in antioxidant capacity during storage time. Phenolic content increased significantly between 3% and 12% for treated samples with 350 MPa and 550 MPa at day 0. The DPPH scavenging activities of the pomegranate juice expressed as an IC50 value were ranged from 11 to 20 mg/mL at day 0. The treated sample at 450 MPa and 550 MPa exhibited the strongest antioxidant capacity (11–13 mg/mL), followed by the control sample (14 mg/mL) and 350 MPa (15–18mg/mL) which showed the weakest activity at day 0.

Pozo-Insfran et al. (2007) evaluated the effect of HPP (450-550 MPa/25 °C/15 min) on antioxidant capacity of Muscadine grape juice during the storage of 21 days at 25 °C. Higher anthocyanin losses occurred at 400 MPa (70%) than at 550 MPa (46%), which were correlated to antioxidant losses. Similarly, greater ascorbic acid losses were observed at 400 MPa (84%) than at 550 MPa (18%). In stored samples, higher anthocyanin content (>2-fold) and antioxidant capacity (>1.5-fold) was observed for copigmented treatments when compared to control juices.

Barba et al. (2012) investigated the effect of HPP (100-400 MPa/20-25 °C/2-9 min) on ascorbic acid, total phenolics, anthocyanin stability and total antioxidant capacity of orange juice–milk beverage. Ascorbic acid retention in the beverage was higher than 91% in all cases after HPP. There was a significant increase (p<0.05) in phenolic compounds at 100 MPa/7 min, however at 400 MPa/9 min, it was observed a non-significant decrease. Total carotenoid content was significantly higher in all samples treated by HPP when treatment time was 7 and 9 min. HPP samples treated at 100 and 300 MPa had significantly lower antioxidant capacity.

Fernández García et al. (2000) compared the antioxidant capacity of HPP treated (400-600 MPa/40-60 °C/5-30 min) apple juice samples during storage at 4 °C. When freshly squeezed apple juice was tested, high pressure treatments were more deleterious than high temperatures, although more than 75% of the total capacity was preserved after extreme conditions (600 MPa/60 °C/30 min). After one month of storage at 4 °C, antioxidant potential of apple juice remained comparable to the one of fresh apple juice at same condition.

Jayachandran et al. (2015) studied the impact of HPP (200-600 MPa/30-70 °C/0-20 min) on the bioactive components in a litchi juice-coconut water-based mixed beverage. An increase in phenolic content (3–12%) and total antioxidant capacity (1–19%) was obtained in the treated beverage samples at 500 and 600 MPa. More than 95% of ascorbic acid has been retained at 30 °C; and it decreased at higher temperature like 60-70 °C.

The increase in antioxidant activity value detected during juice and beverage processing could be due to the extraction of some of the hydrolysable tannins, present in the fruit rind, and/or related to the increase in phenolics or ellagic acid, ellagic structures polymerised into ellagitannins, and/or anthocyanin polymers formed during the storage period. Reported loss after extreme high pressure conditions may have been generated by changes in juice redox properties during pressure build-up or by adiabatic heating of the samples inducing chemical reactions (Fernández García et al., 2000). In presence of oxygen, oxidative processes occurred rapidly and storage increased extensive losses. High pressure was in these cases markedly beneficial directly after treatment.

4 Concluding Remarks

Increasing market for fruit juice and beverages induced the industry people to ensure their stability, and also to avoid unpleasant aspects like off-flavour formation, while extending shelf-life of the final produce. This triggers the necessity of searching for new ways of processing like high pressure processing of these products. Different studies on the fruit-based beverages presented guarantee high pressure as a promising technique being non- detrimental and even advantageous for the total antioxidant profile of the juice or beverage. These compounds may be affected at higher pressures like more than 800 MPa which results in degradation in vitamins and fragmentation of larger flavouring compounds. The temperature associated with high pressure are the major contributing factor behind the thermal degradation of these bioactive components. However, more emphasis is required for specific beverages to find out the optimum treatment condition satisfying the consumer demand for safety, stability and nutritional quality.