The products have been developed with safety in mind and h the improved design also makes them easy to install.

Commercial Manager Sue Springett said: “We listen closely to customers and there were two particular issues that come up time and time again in relation to knife sterilisers: the first is maintaining temperature control above 82°C and the second is repairs and downtime – a problem when staff forget to top up the water.

“Hygiene control means the water temperature cannot dip below 82°C. It’s something BRC auditors are always on the lookout for. While we can’t be on hand to remind users to keep the tank topped up, we have made the design more forgiving should there be the occasional memory lapse.”

The design of the knife sterilisers minimises the risk of the water boiling dry. The overflow ensures they retain the correct amount of water and as much internal space as possible has been freed up for water within the units.

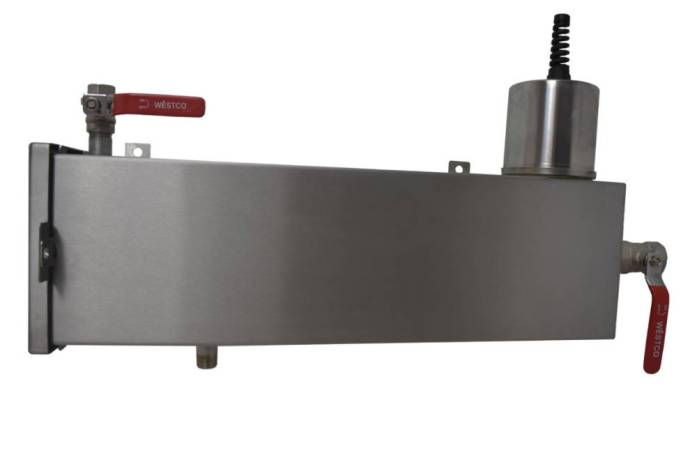

The element and thermostat are housed externally, which also makes it easier and quicker to rest or change them if necessary. The products also feature an external low water cut-out, which reduces the margin for human error.

Daryl Goldstone, Maintenance Engineering Supervisor at Tulip Meats, said: “Teknomek’s great strength is that the team really pays attention to customers’ feedback and this is reflected in the improved design. I estimate that we will save as much as 30 minutes a week because of these updates.

“I’m often surprised that more manufacturers don’t do the same. The beauty of the new units is these apparently small details make a big difference to our operational efficiency.”

A hinged lid provides greater safety to the user when filling the unit, this is down to a flow deflector that channels the water to limit splashing. The plumbed inlet ball valve is WRAS approved offering peace of mind that no waste water can find its way back into the main water supply. WRAS approval means these products can be installed in new build applications.

Internal channels direct waste water into a wide outlet at the base of the unit, saving drainage time after each use and is also less likely to become blocked by debris.

The knife sterilisers are built of hard-wearing and hygienic 304-grade stainless steel and each comes with integral wall fixings offering simple installation and providing access for all round cleaning.

Source:fdiforum.net/