The country’s food grain production for the crop year 2011-2012 has been estimated to be about 250 million tonnes. This will be the highest production record of all.

Modern silos

Adding to that, the Indian government along with FCI (Food Corporation of India) is considering tenders for the construction of modern silos with scientific storage facility that includes aeration system. This huge initiative has been taken to overcome grain spoilages occurring due to inadequate and bad storage facility.

The technology transfer from gunny bag handling to storing the grain in modern silo saves too many labours, ensures that less space is required compared to warehouse and enables lesser material handling losses.

Grain cooling

These facts are already realised by the Oil Federation of India and FCI on their previous experiences in large-scale bulk storage of oil seeds (soybeans) and cereals in silos equipped with simple aeration system but not the advanced grain cooling system.

The grain cooling system is practiced for more than 50 years in Europe and Western countries and this technology is advanced than simple aeration (blowing ambient air in the grain bulk).

New for India

Since, India is going through rapid transformation in grain storage from gunny bag handling to silo system, therefore, grain cooling is completely a new technology for India and it is important to understand why aeration or grain cooling is required for bulk grain stored in silos or warehouse.

Secondly, it is important how the advanced grain-cooling guarantees harvest freshness for more than six months just by running the units for not longer than three weeks and without infestation.

Post-harvest handling

Generally, post-harvest handling of grain requires treatment of the bulk to prevent hot spots, deterioration, and growth of fungus & weevil infestation. Even if the grain is dried to a level, when long term storage is possible, the grain remains active because of respiration. The result is hot spots and water which increase the activity of the grain, fungus and weevil. What can be expected from aeration and why is it limited in its success?

Aeration

First of all, aeration uses ambient air in treating the heat. The ability of that air to reduce the heat is limited under tropical condition where the ambient temperature is high most of the time. The air is only able to take the excess heat from the grain which is above the ambient temperature. Therefore the temperature of the grain bulk remains relative high which results in high activity and heat production.

The activity leads to continuing high respiration rates which result in high dry matter loss of carbohydrates and water accumulation in the bulk. Firstly, it leads to economical loss directly, secondly, increases the living conditions for other hazards and thus in secondary loss of grain and its quality.

Cooling is better

From that what was mentioned so far it is obvious that grain cooling conservation can do better.

The air which is used for treating the grain is lowered in temperature and the temperature difference of the air and the grain is higher which allows the heat reduction faster as aeration can do. Thereby the air does not only take the heat which is generated by the respiration but it lowers the temperature of the bulk itself. This results in less respiration and heat generation thus in lower dry matter loss and less water accumulation. At the end of the bulk cooling, the respiration is almost zero and no further loss or damage happens.

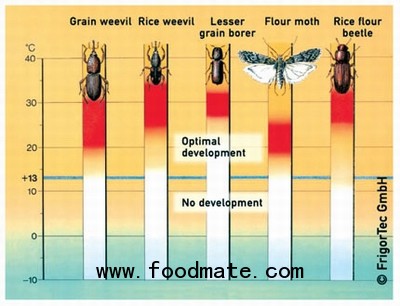

During aeration the weevil and fungus activity is supported because of water generation by respiration. This increases the water activity at the bulk and the risk of deterioration as well as losses because of weevil infestation. Grain cooling conservation uses the nature of weevil and fungus to stop their activity at lower temperatures as shown for weevils in Figure 1. Thereby any potential loss is stopped and the grain is preserved.

Summing up

India has revised its grain storage facilities with modern silos in order to overcome grain loss. In a similar fashion, the country has to realise the quality issue when targeting export market and grain cooling technology by Granifrigor is an ideal solution.