The success of Xtend ? for asparagus is continuing to grow in these and other territories. Here are a few tips on handling asparagus for enhancing the performance of the packaging.

Postharvest treatment of asparagus - Minimize Temperature Damage Immediately After Harvest

Asparagus is highly perishable due to its high respiration rate. Since respiration rate is directly proportional to temperature, the higher the temperature, the faster the rate of deterioration. There are certain actions that should be taken during and immediately after harvest to minimize deterioration.

It is highly recommended to harvest the asparagus in the early hours of the morning or alternatively in the late afternoon hours when daylight temperatures are at their lowest.

Spears should ideally be packed in light colored, well ventilated crates to reduce heat absorbance.

Crates should not be filled to more than ? of their depth so that ventilation is not impaired and mechanical damage is minimized.

After harvesting crates should be kept in the shade until transporting them to the packing house.

When packing crates make sure that they do not come into direct contact with the soil as this is likely to result in contamination which will increase the risk of decay.

It is advised to make frequent trips to the packing house to enable prompt removal of field heat.

Transport to the Packing House

If the transport distance is short, then this may be done in covered trucks. When the travel time from the field to the packing house exceeds 1 hour, a refrigerated truck should ideally be used.

Upon Arrival at the Packing House

Upon arrival at the packing house, the asparagus should be hosed down with potable water to remove any mud and dust. Make sure that the water pressure is not too high to avoid damaging the spears.

Immediately after first wash, the asparagus should be further washed by placing the crates in a bath containing clean water with disinfectant. 100-150 ppm chlorine, maintained at pH 6.5-7.0 is commonly used, but peracetic acid is becoming ever more popular alternative for disinfection.

This wash should be combined with hydrocooling to remove some of the field heat and reduce temperature to 10°C (50°F). Monitoring of the water chemistry should be done continuously. The water should be filtered and changed frequently if re-circulated.

Hydrocooling

Storage after first hydrocooling:

After the asparagus has been washed and hydrocooled to ~10°C (50°F), it should be placed in a waiting refrigerated at 5-10°C (41-50°F) with a relative humidity > 90%. The produce should remain in the waiting room for no longer than half a day.

Sorting, Trimming and Bunching

If cutting is done manually, the cutters should be kept clean by regularly cleansing with a disinfectant. The cutters must be sharpened regularly and the asparagus should be placed on a hard surface whilst cutting in order to obtain a smooth cut. Avoid damage to the butt.

If cutting is done by machine, the cutter should be continuously disinfected (by spraying for instance), kept sharp and the asparagus fixed during cutting to ensure a smooth cut.

The work area in which this is done, should be kept at 10°C (50°F)

Second Hydrocooling

After sorting and bunching, the asparagus should be hydrocooled for a second time until the central bunches in the crates/boxes reach 1°C (34°F). Shower hydrocooling of asparagus bunches stacked in plastic crates/boxes is preferable.

The water should be disinfected as before.

Drainage

Following hydrocooling, the asparagus should be left in cold storage at 0.5-1.5oC (33-35°F) for 30-60 minutes to drain excess moisture (Preferably, the produce should be conveyed through a hatch into the cold room). The relative humidity in the cold storage should be greater than 90%.

Do not drain for too long as it will result in some dehydration of the produce.

A forced air system can be used to accelerate the draining process.

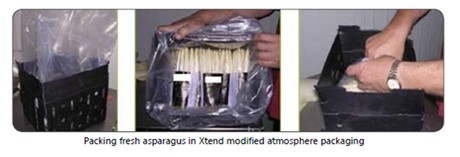

Packing

Asparagus should be packed the same day that it is harvested.

Ideally, packing should be done in the cold storage at 0.5-1.5oC (33-35°F). Workers need to be dressed accordingly to work at these temperatures.

Asparagus must be free of excess surface moisture before packing in Xtend?.

StePac's Xtend? modified atmosphere / modified humidity )MA/MH) packaging for asparagus is ideal for maintaining and enhancing freshness and quality in this extremely competitive market.

By enabling cold storage for up to 28 days with another, Xtend? for green asparagus allows suppliers to better control flow of produce to retail points of sale. Xtend? for white asparagus maintains quality for in the vicinity of 40-45 days mainly due to the lower respiration of white asparagus.

Packaging designs differ for white and green asparagus, but both minimize shriveling, spear toughening and butt dehydration.

Decay is inhibited due to Xtend? technology's combined modified atmosphere and condensation control (modified humidity). Xtend? for green asparagus preserves green, glossy appearance of tips and minimizes feathering while Xtend ? for white asparagus inhibits browning.