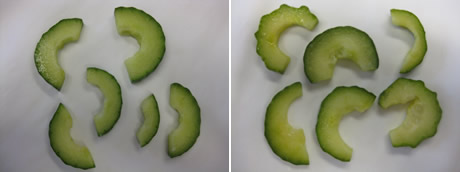

"The old machine, which worked with a kind of apple drill/punch, caused a very irregular cut of the cucumber half moons. The seed rows were not removed enough and the machine cut out the flesh in some places as well," says Jan van den Eijkel of VDE Systems.

The new seed remover produces the best half moons by far, with the best shelf life, as only the seeds are removed and the flesh remains untouched, it keeps a firm bite and retains the specific cucumber flavour and they are real half moons. The largest advantage is the shelf life. It is extended by 2 to 3 days and all the flesh remains.

The difference of the former seed remover's way of producing is that in the old one there are still parts of the seeds on the the cucumber half moons. The stress caused by punching the cucumber also caused a higher respiratory rate which meant the packaging inflated faster," concludes Jan.