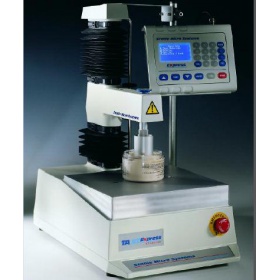

s, expert in texture analysis, has announced the launch of its Dynamic Integrated Balance for use in conjunction with its world-renowned TA.XT plus texture analyser. Forming part of Stable Micro Systems’ growing range of supplementary measurement options, the latest accessory enables users to measure an additional ‘weighing’ parameter during standard force measurement tests.

s, expert in texture analysis, has announced the launch of its Dynamic Integrated Balance for use in conjunction with its world-renowned TA.XT plus texture analyser. Forming part of Stable Micro Systems’ growing range of supplementary measurement options, the latest accessory enables users to measure an additional ‘weighing’ parameter during standard force measurement tests.The new measuring platform means users cannot only quantify the ease of removal of product contents, but also accurately determine the delivered quantity and rate of delivery as a result of the exerted force.

The Dynamic Integrated Balance will be of particular interest in those tests where product is removed or deposited from the component that is being tested - particularly in extrusion or actuation testing. Typical applications of this vary and can comprise food sachets and pouches, toothpaste, hand soap dispensers or syringes. As such, the configuration between the texture analyser and the dynamic weighing system means that during the extrusion or actuation test, the deposited amount of product can be weighed at the same time as force, distance and time data is collected at high speed. In addition to this, once the test is complete, users are able to analyse the amount and rate at which the product was deposited on a second axis alongside their usual force data.

Jo Smewing, applications manager, Stable Micro Systems adds, “The new weighing system can accurately collect data from 500 points per second as well as having other functional benefits including full mechanical overload protection of the loadcell and 100g sensitive capacity.”