ing solutions specialist, tna, has announced the launch of the new tna roflo® VM 3 high throw vibratory conveyor. The unique high throw design achieves the gentle transfer of sticky confectionery and difficult products, such as loose leaf fresh produce, through increased vertical motion to improve product throughput and line efficiency.

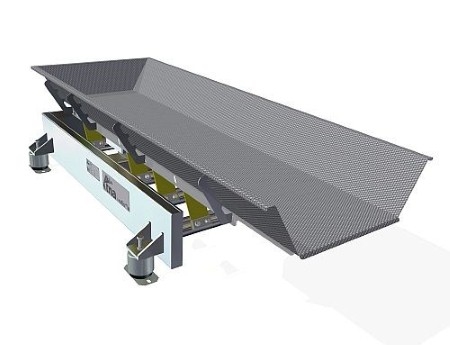

ing solutions specialist, tna, has announced the launch of the new tna roflo® VM 3 high throw vibratory conveyor. The unique high throw design achieves the gentle transfer of sticky confectionery and difficult products, such as loose leaf fresh produce, through increased vertical motion to improve product throughput and line efficiency.Building on tna’s existing innovative technology, the latest incarnation of the tna roflo® VM 3 overcomes the specific challenges of conveying fresh produce and sticky confectionery. These products often suffer from clumping and tend to stick to regular vibratory conveyors. This can slow down, or even stop, product distribution, drastically reducing line efficiency. To prevent this from occurring, the new tna roflo® VM 3 high throw conveyor incorporates an innovative reaction base design, combined with an intelligent microprocessor, which achieves a much greater stroke length at a lower frequency. This allows greater distance to be travelled, both linear and in elevation, per cycle, and fewer times per second relative to standard vibratory motion conveyors, to achieve smooth transfer of these previously challenging products.

The tna roflo® VM 3 high throw conveyor is a full stainless steel wash down construction and, like all other tna vibratory conveyors, operates at natural frequency, greatly reducing power consumption. The pan material can be supplied in either dimpled or a standard flat finish, depending on the application requirements. Offering reduced surface contact with the product, the dimpled design works in synergy with the greater stroke length at a lower frequency to deliver the ideal conveyor for sticky and hard-to-transfer products.

Roger Treacher, group sales manager – conveying, tna, comments, “We’re delighted to be bringing this new product to the industry. The new tna roflo® VM 3 high throw vibratory conveyor is a great addition to our extensive range of distribution solutions. Traditionally a challenging area for food manufacturers, the new high throw distribution system transfers sticky confectionery and fresh produce quickly and easily, increasing efficiency and reducing downtime for cleaning or repairs.”