genbau of Sankt Augustin, Germany, and DuPont Packaging & Industrial Polymers (DuPont) have brought together Kuhne’s TripleBubble® water-quenched and bi-oriented film technology and DuPont’s knowledge in high-performance packaging polymers to explore new ways of saving costs and materials in multilayer shrink and lidding film applications.

genbau of Sankt Augustin, Germany, and DuPont Packaging & Industrial Polymers (DuPont) have brought together Kuhne’s TripleBubble® water-quenched and bi-oriented film technology and DuPont’s knowledge in high-performance packaging polymers to explore new ways of saving costs and materials in multilayer shrink and lidding film applications.With highly transparent films downgauged for a reduced environmental footprint, new shrink bag and film structures using DuPont™ Surlyn® are intended to provide a multitude of advantages over existing solutions, including advanced meat adhesion as well as excellent puncture resistance, extending shelf life and minimizing food waste caused by packaging failure during transportation.

Initial laboratory results from testing new lidding film solutions using DuPont™ Appeel® as sealing layer as well as DuPont™ Bynel® as tie layer are demonstrating that combining TripleBubble® Technology and sophisticated DuPont packaging materials permits raw materials savings of up to 50 percent over conventional laminate structures, depending on the application, as well as energy savings, and consequently significantly improved life-cycle analysis results.

TripleBubble® shrink films typically consist of a PET- or PA-based outer layer, a structural layer based on DuPont™ Surlyn® and a PE-based seal layer, and can be enhanced with an EVOH or PVDC based barrier structure. Here, the partially cross-linked thermoplastic ionomer Surlyn® is key to their high shrink, softness and perforation resistance. A new joint development from Kuhne and DuPont is the combination of conventional shrink film technology using Surlyn® as shrink layer with an advanced sealing technology, where Surlyn® is used also as sealant. This approach opens up new horizons in shelf life and product presentation.

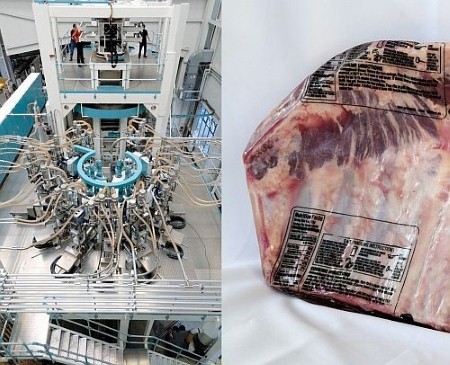

By far the most advanced and most widespread application of such shrink films is the production of shrink bags, used to transport meat on the bone from the slaughterhouse to retailers or restaurants. A fast-emerging new trend is to use shrink bags for supermarket consumer packaging, the reason being that such films adhere tightly to the meat without any protruding edges and improve color, odor and meat texture. What’s more, compared with the tray-and-lid weighing around 14 gm that they replace, shrink bags for retail applications only weigh 4 gm and can thus significantly improve the sustainability of supermarket meat packages.

To support this major industry trend, DuPont and Kuhne have recently focused their joint development on using new, dedicated Surlyn® grades to further optimize the shrinking and sealing performance of TripleBubble® shrink bag and barrier shrink bag structures. Used not only as shrink layer but also as sealant layer, these new grades open up new routes to novel, appealing and sustainable structures featuring a superior balance of puncture resistance, flexibility, softness, seal performance, transparency and shrink behavior. In particular, the use of Surlyn® for food contact layers in shrink bag applications has resulted in improved transparency, meat adhesion and color as well as reduced drip and odor development.

Lidding Films with Controlled Thermal Stability

A further focus in the ongoing collaboration between Kuhne and DuPont is on downgauging of strong coextruded and bi-oriented high-performance films with controlled thermal stability for lidding applications. Current developments include films with up to 11, and in future, even 13 layers of functional polymers, including DuPont™ Surlyn® ionomers or DuPont™ Appeel® resins as sealing components for peelable, easy-open packaging solutions as well as application-specific DuPont™ Bynel® adhesive resins as tie layers, which remain highly effective even after stretching and relaxation.

The TripleBubble® technology significantly enhances the mechanical properties of such films due to the high level of molecular orientation brought about by biaxial stretching. Thermal relaxation, which occurs in the third bubble of the process where film shrinkage is reduced to a controlled value, is a particular challenge. Here, the effectiveness of the tie layer, which bonds incompatible functional layers of the structure together, is of major significance for producing high-tear and puncture-resistant films which are nevertheless comparatively thin.

In a first stage of their joint development, DuPont and Kuhne have investigated the effects of tie layers offering good adhesion between PET and polyolefins, such as PE, PP or ionomers, between PO and PA and between PA and the heat-sealing layer. As a result, DuPont has developed a standard tie layer range, providing resistance during the production process, matching the viscosities of other polymer types used and adhering well to the two substrates during orientation and after thermal relaxation. This range includes DuPont™ Bynel® 21E787 and 22E780, which are suitable for PET/PO, or Bynel® 41E687, which is suitable for PA/PO, with optimization for other fields of application still underway.

Kuhne’s TripleBubble® Technology

This technology is dedicated to the production of bi-oriented blown films for advanced food packaging applications, including meat, sausages and cheese, providing advantages such as high oxygen barrier. Since 1996, when Kuhne first developed this technology, the company has continuously extended its product portfolio, which today ranges from high-speed mono-systems for sausage casings with production speeds of up to 300 m/min, via medium width co-extrusion systems for multi-layer food packaging films, up to large size systems for film widths of up to 1.9 m, providing extremely high barrier and mechanical properties.

A standard feature of all TripleBubble® Systems is quenching of the first bubble using water chilled to 4 to 6°C. This water quench technology was developed for the TripleBubble® process by Kuhne in 1996 to permit significantly higher cooling rates compared to other production processes, preventing the development of crystallinity in the film and enabling a uniform downstream orientation process. In 2008, this concept for the production of water-quenched blown films was extended to produce films of up to 11 layers. Moreover, TripleBubble® technology has recently been further developed to include up to 13 layers and large film widths and outputs of over 1 tonne per hour and to convert all common raw materials, including PE, PP, PET, PS, PA, EVOH, COC, EVA, EMA, ionomers and more.

The engineering company Kuhne Anlagenbau GmbH, a member of the Kuhne Group, is dedicated to developing specific blown film technologies for the production of high-tech films for the food processing industry, the medical sector and demanding industrial applications. Kuhne achieves this by developing and optimizing specific machine technologies, mature finished products (films) for flexible packaging manufacturers, specially tailored raw materials in collaboration with raw material manufacturers as well as products and processes in collaboration with customers and research institutes.