The technology comes from the need to quickly cool fresh produce such as soft fruit and lettuce. What can take up to 12 hours to cool with other techniques, the mobile pre-cool unit achieves this within 35% of the time it would normally take. This results in quicker transport, less energy use and longer preservation. Not only is there less waste produced, costs are also brought down. Therefore all relevant parties benefit, or as it is known in corporate social responsibility terms: People, Planet, Profit.

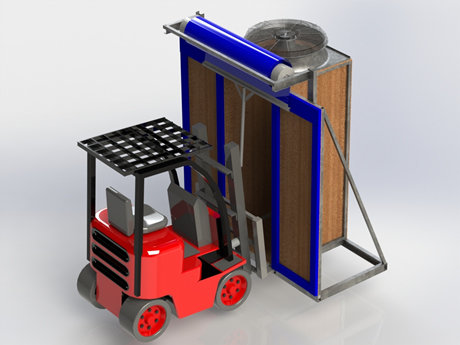

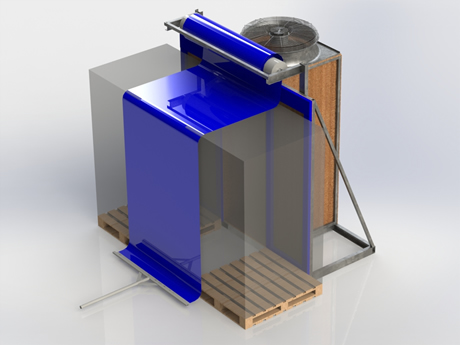

The mobile pre-cool unit pulls the cold ambient air over the product by means of a fan and canvas which can be easily operated electrically. As the ventilator can produce up to 20,000 square meters of cold air per hour and thereby can cool a maximum of 24 pallets, it is also energy efficient.

This innovation is for BG Door International a logical next step after 25 years of great success with the maturing room doors, especially used for banana's and tropical fruit. To be able to fully realise the development of the new technique, BG Door International has teamed up with Van der Heiden Systems. Both companies bring indispensable qualities: where Van der Heiden Systems have more expertise in the area of ripening, BG Door International has more experience in international trade.

All and all, this innovation is a hugely welcome addition to become more sustainable with fresh produce. It offers not just opportunities for wholesalers in the Netherlands, but also for smaller and international orientated exporters. The most important fact remains, of course, that BG Door International offers a technique whereby the quality and preservation of a product increases, while reducing cost and waste.