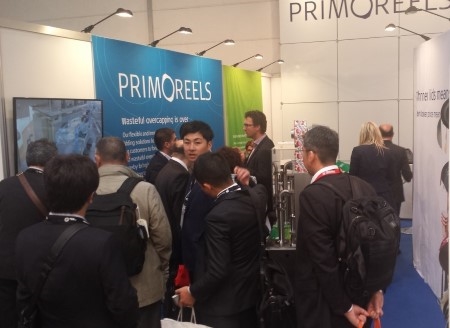

the company has shown its latest four-row model of a Stand Alone unit, which is for rebuild of existing filling lines, to be able to run the Primoreels lidding system.

the company has shown its latest four-row model of a Stand Alone unit, which is for rebuild of existing filling lines, to be able to run the Primoreels lidding system. Primoreels A/S has become an established flexible packaging partner for manufacturers in the dairy sector and the water/juice industry. The Primoreels® system is successfully installed on numerous high capacity machines around the world. Now the Primoreels® system can be adapted to any type and brand of filling machine - Inline machines as well as Round table machines. The units are tailor-made and have their own touch screen panels and controls, making them independent units.

Compared to regular die cut PET & Aluminium lids, the Primoreels PET lids offer the best substitute in regards of a cheaper lidding material that at the same time minimise the environmental impact. Reinforcing its commitment to the environment, Primoreels can offer the most popular and commonly used PET lids in 36 microns - but also PET lids as thin as 23 microns, and paper based materials with even lower carbon footprint.

Users of the new solution benefit from:

o Up to 40,000 lids on a reel - many hours of production

o High print quality - completely smooth surface

o No waste material in production

o Low environmental hazard - lids as thin as 23 microns with lower carbon footprint

o UV-C sterilized lids - low risk of contamination

o An increase in shelf life of various products, high barrier properties.

o Efficiency of production lines and staff reduction compared to the lines, where the personal applies individual stacks of lids.

o Reduction of storage space for your packaging.

o Primoreels® runs on automatic filling machines with capacities up to 45 cycles/ minute.

o Ability to install the equipment on existing lines of different manufacturers, giving the customer an immediate advantage.