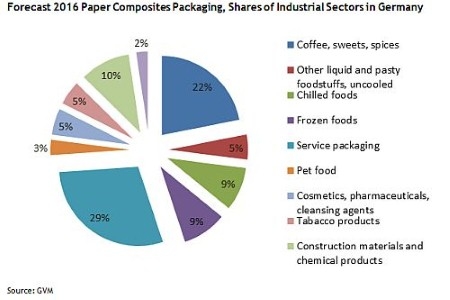

terial prices, supply bottlenecks and falling profit margins drive packaging manufacturers to resort to creative solutions. As an alternative to plastic packaging a trend towards paper packaging with barrier properties is emerging. Key findings of the latest report of the German market research institutes GVM and sciendea+ show that chilled foods, frozen foods, service packaging for catering (e.g. fast food) and pet food are especially profitable markets for innovative paper composites.

terial prices, supply bottlenecks and falling profit margins drive packaging manufacturers to resort to creative solutions. As an alternative to plastic packaging a trend towards paper packaging with barrier properties is emerging. Key findings of the latest report of the German market research institutes GVM and sciendea+ show that chilled foods, frozen foods, service packaging for catering (e.g. fast food) and pet food are especially profitable markets for innovative paper composites. New coating technologies set high expectations for the market growth of paper composites. Results of a GVM market survey show that functional barriers to oxygen, water vapor and aroma are getting more important. While the barrier properties of paper composites are continuously increasing, the film weight is decreasing. Aluminum laminates are substituted by coated papers. Wet coating is declining and is replaced by extrusion coating.

In addition, the special appeal and haptic of paper is becoming more significant from a marketing point of view. Visually outstanding packaging is demanded by fillers to clearly set apart from competition. As an example the optical packaging designs vary from rough to smooth and matt to shiny. Retail is driving this development by demanding successful marketing by effective presentation. Products, which offer an incentive to purchase by a successful combination of brand character, brand recognition and price, have a clear competitive advantage.

To date, plastic can be processed more cheaply and more effectively than paper composites, particularly for sealing and thermoforming applications. Though, market potential is seen for paper lids and trays for chilled food like for salmon, cold meats or cheese.

Essentially, the chances of success for paper-based packaging depend on manufacturing costs compared to those of plastic packaging. Increasing lot sizes will enlarge the efficiency of paper composites production. At the end of the life cycle paper packaging already has a clear benefit towards plastic through lower license fees to disposal companies.

The new paper composite generation can also be a rewarding niche for packaging manufacturers. The competitive landscape is mainly determined by two different business models.

The so called “Integrated multinational packaging manufacturers” are characterized by a high degree of horizontal and vertical integration. This business model promises cost savings by economies of scale and thus a high level of profitability. Servicing high volume markets with simple or medium complex paper composites (eg. service packaging for catering or pet food) are their main success factor. Mondi, Stora Enso, Huhtamaki are examples of those multinational players.

The “small and medium-sized specialists” are characterized by a high degree of innovation activity. They tend to work in a network of cooperation partners and team up with raw material suppliers, bottlers and retailers to develop tailor made and complex paper composite solutions for chilled food such as meat, sausage, fish, or hard and semi-hard cheese. Wipak, Leeb and Leipa rank among those specialists.

To date, profit margins for those complex paper composites are quite low, but this will change on the long run as the demand for sustainable packing solutions will increase in the future.