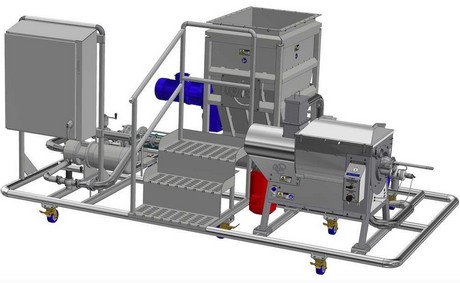

The result of two years’ research involving prototypes and precursors, the FVP (Fruit and Vegetable Processing) skid incorporates JBT’s chopper pump, the FVX-5, with an external FVG flow-through grinder and a UCF110 screw finisher. The company notes that no heat is applied during extraction, making the juice or blends suitable for immediate bottling followed by HPP processing with JBT’s Avure high-pressure processing systems.

The solution

Danny Milla, JBT’s New Product Development Manager for Fruit & Vegetable Processing, said: “The idea for this skid is to provide a modular system that can process any fruit and vegetable in a hygienic fashion. Three pieces of equipment are mounted on the skid and together provide the solution. Based on research and testing over the last two years, we have proven the concept and now we have created a new product that encapsulates this equipment on a single skid at a single price.”

JBT says that unlike a traditional bag press – an accordion-like structure, which squeezes the pulped produce through a nylon cloth – the FVP does not require emptying and refilling after each batch. Instead, the FVP offers continuous processing, which is hygienic and easy-to-clean, while at the same time being completely enclosed.

The company states: "Easily automated, the FVP can also handle up to five tons per hour, and delivers a yield of anywhere between 50 percent to 92 percent across a range of commonly processed fruits and vegetables. Depending on the product it can generate up to 20 gallons per minute of fresh juice."

The first completed FVP is expected to be ready for commercialization in January 2019.