om the University of Western Australia (UWA) are developing quality control systems for unprocessed and processed food items using infrared technology.

om the University of Western Australia (UWA) are developing quality control systems for unprocessed and processed food items using infrared technology.Funded by an Australian Research Council grant, the project is aimed at developing rapid and non-destructive ways that provide substantial benefits to the industry.

The approach is similar to infra-red thermometers used to detect fever in humans or animals.

UWA Institute of Agriculture and School of Animal Biology associate professor Christian Nansen said that he is looking at how the same technology can be used to class food products.

Nansen added, "With this technology, food items moving down a conveyor belt can easily be 'tagged' by an infra-red scanner, and fast computers can quickly analyse the imaging data and determine whether or not a given food item needs to be rejected, or whether it needs to be diverted to the cargo bin for lower-grade food items.

"It is similar to the baggage handling system at an airport: the infra-red scan taken along the conveyor belt represents the 'tag' which ensures that each item of luggage - or fruit - gets to the right cargo bin and airplane."

Nansen said that developing quality control systems using imaging technology is a rapidly growing and expanding research area. It includes detecting and quantifying defects in grains, fruits and vegetables, pesticide residues, and meat quality.

As food items such as, fruits and vegetables vary in size, surface texture and colours classification based on surface colour is associated with low classification accuracy, he noted.

For the research, which was published in the Journal of Food Engineering, Nansen has teamed up with associate professor Guijun Yan, Nader Aryamanesh and student Xuechen Zhang at the university, to explore whether this technology could also be used to detect weevil infestation inside field pea.

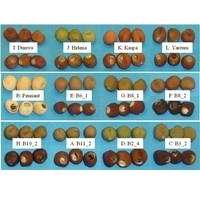

The team used 12 varieties of field peas with and without pea weevil infestation with pea varieties comprising a wide range of background colours and compared different classification methods.

One developed by Nansen's group was found to be more conventional classification methods, paving the way for accurate large-scale, commercially viable classification of food items that can be performed under significant time constraints.